- KINGRANTEE TECHNOLOGY -

ABOUT US

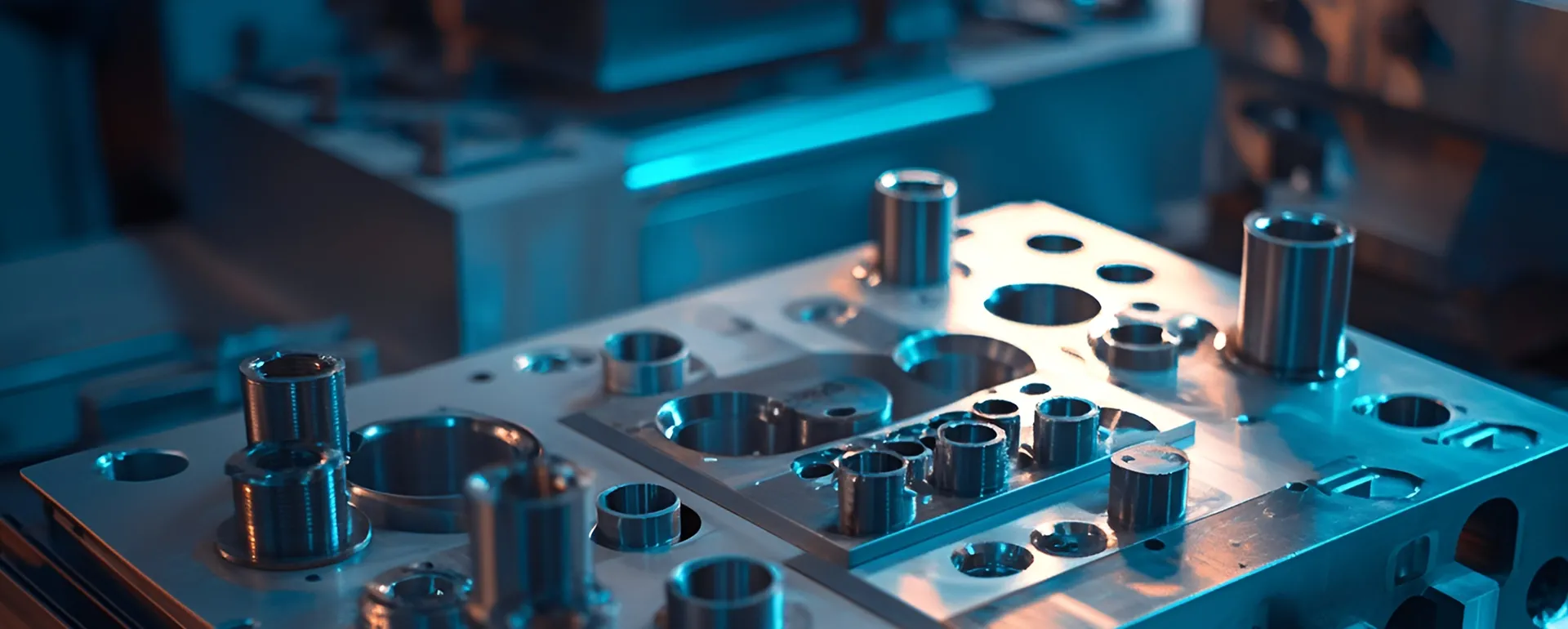

Shenzhen Jinyuanxing Metal Die Casting Products Co., Ltd. was established in September 2004, with its headquarters located in Shenzhen. The total investment scale amounts to 60 million yuan, covering an area of approximately 25,000 square meters. As an intelligent manufacturing enterprise integrating R&D, production and technical services, the company has been deeply engaged in the design and manufacturing of zinc/aluminum alloy die-casting molds and plastic molds, and has established a full industrial chain service system from die-casting molding, injection molding processing to precision post-treatment. Covering core processes such as CNC lathe processing, precision machining with computerized lathes, grinding and polishing, drilling and tapping, and surface spraying, we can provide customers with one-stop intelligent manufacturing solutions.

In September 2013: To deepen international business cooperation and expand the global market, Jinyuanxing Technology Development (Hong Kong) Co., Ltd. was established, building a bridge for efficient connection with overseas customers.

In November 2018, along with the continuous growth of order scale and the trend of diversified customer demands, the company initiated a capacity expansion strategy and established Jinyuanxing Technology Development Co., Ltd. in Jiangxi Province to further enhance production synergy capabilities.

In November 2023, the Jiangxi production base completed the expansion and upgrading of its industrial park, increasing the total area to approximately 55,000 square meters. Through the layout of intelligent production lines, the comprehensive competitiveness of the enterprise was significantly enhanced.

Technological innovation and business expansion

In April 2021, the company introduced the third-generation high-performance injection molding machine from Haitian, comprehensively expanding its business territory in plastic products and achieving full-process intelligent integration of die-casting, injection molding, mold development and CNC precision parts processing.

At present, our products have covered more than 20 high-end manufacturing fields, including new energy vehicles, photovoltaic energy storage, military equipment, industrial communication equipment, LED lighting, intelligent security (including facial recognition systems), auto parts, home appliances, rail transit and aerospace components, medical equipment, sports equipment, electronic display devices (such as monitor casings, TV accessories), instruments and meters, motors, etc.

- PRODUCT APPLICATION -

Provide Customized Services

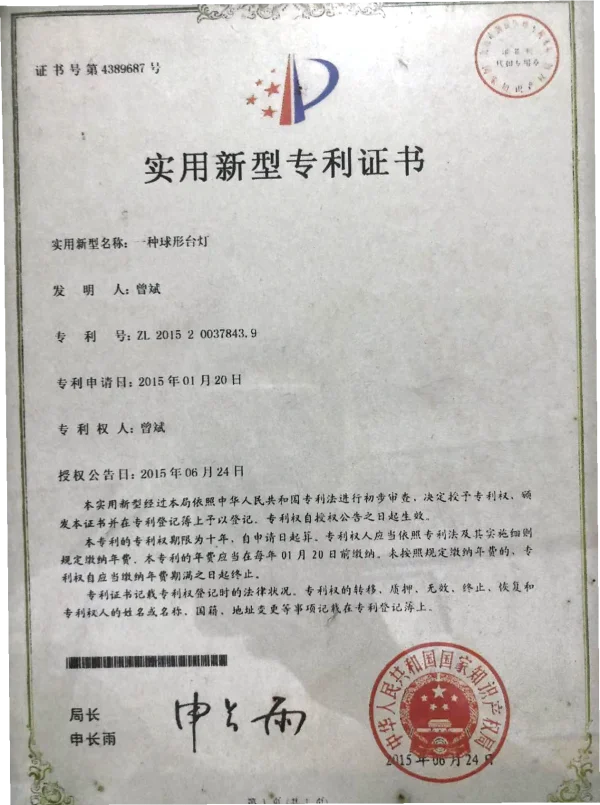

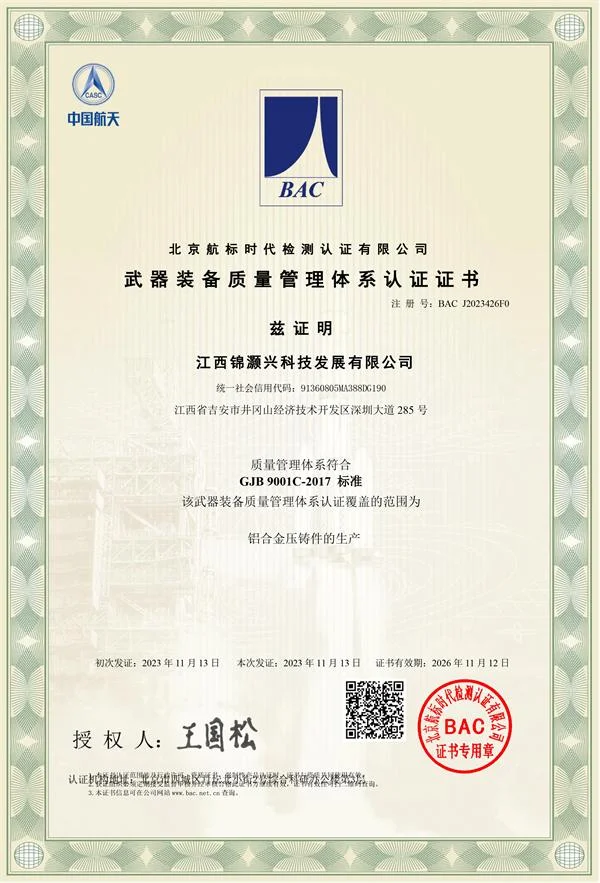

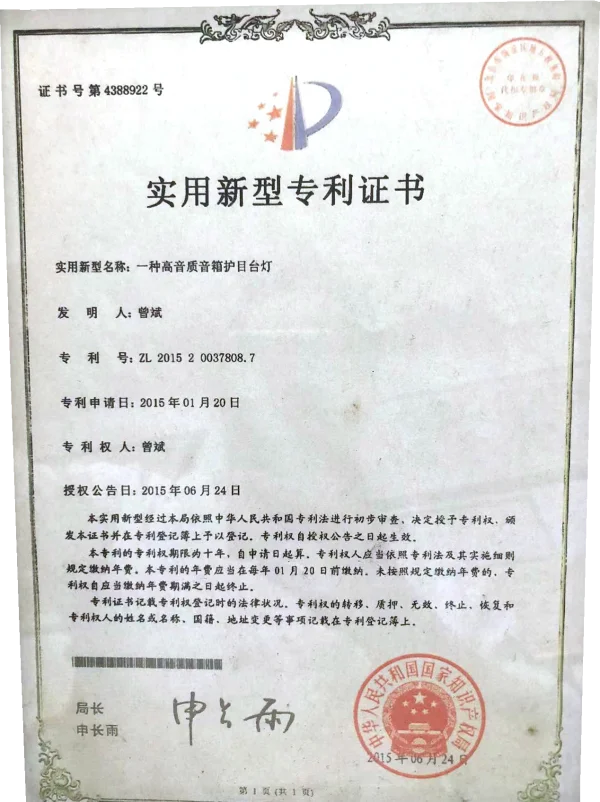

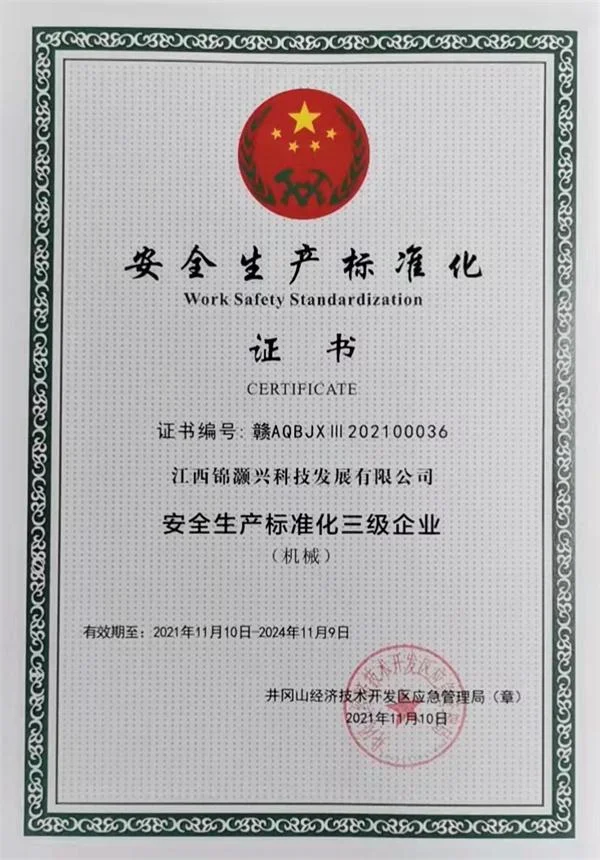

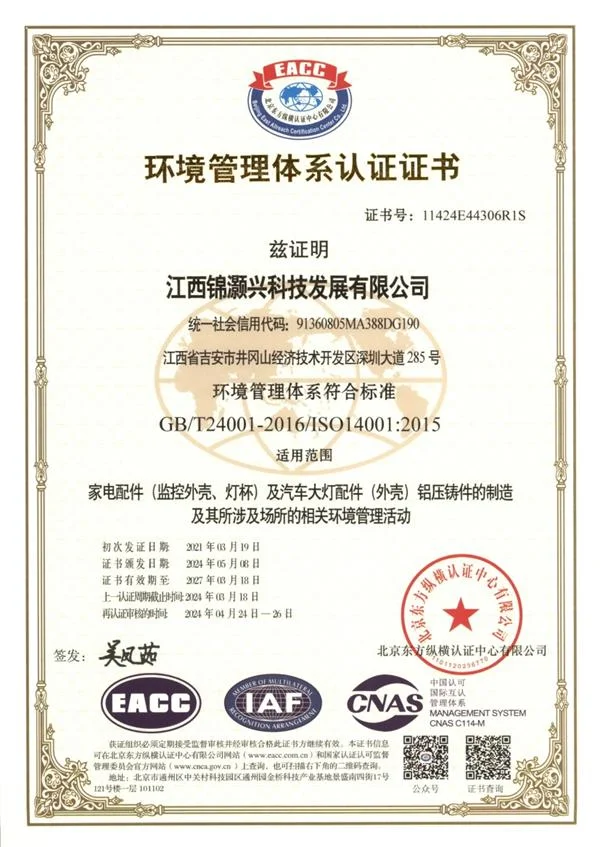

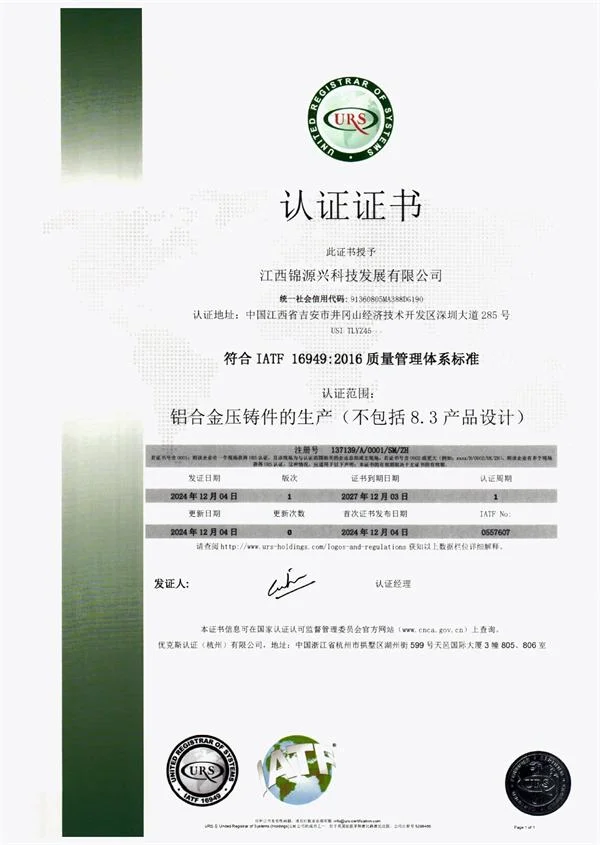

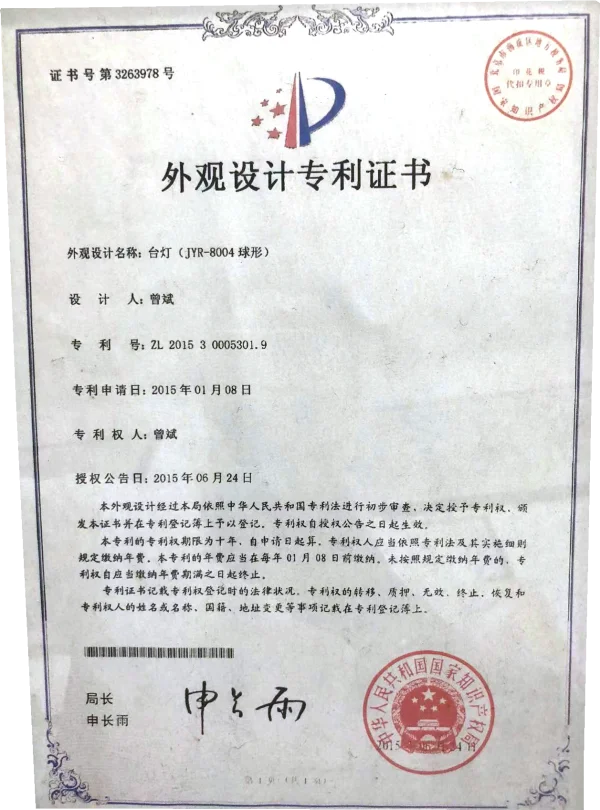

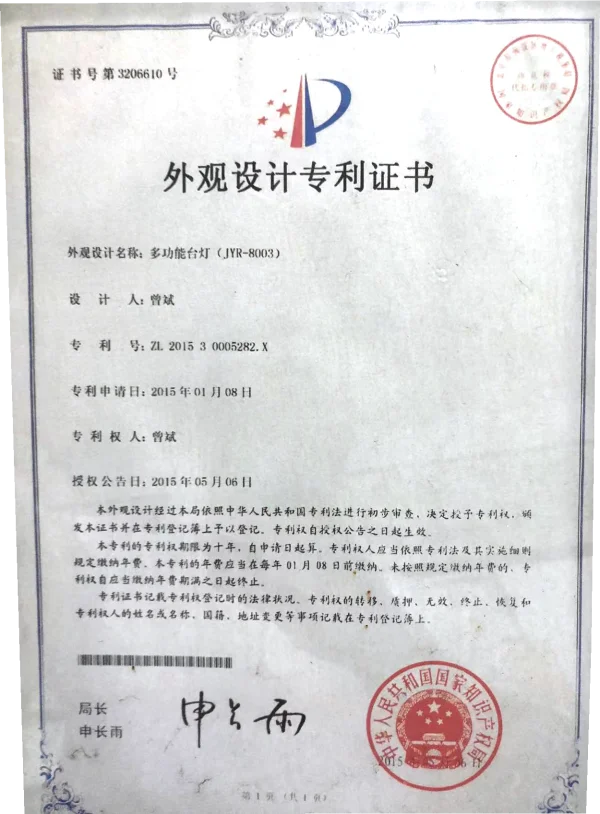

- CERTIFICATE OF HONOR -

Qualifications and Honors

Since our establishment in 2004, we have always adhered to the concept of "quality first" and have obtained many certifications and honors in the process of continuous development. In the future, we will create higher value for customers and the industry with a more rigorous attitude.

- OUR SERVICES -

Personalized Customization to Meet Your More Needs

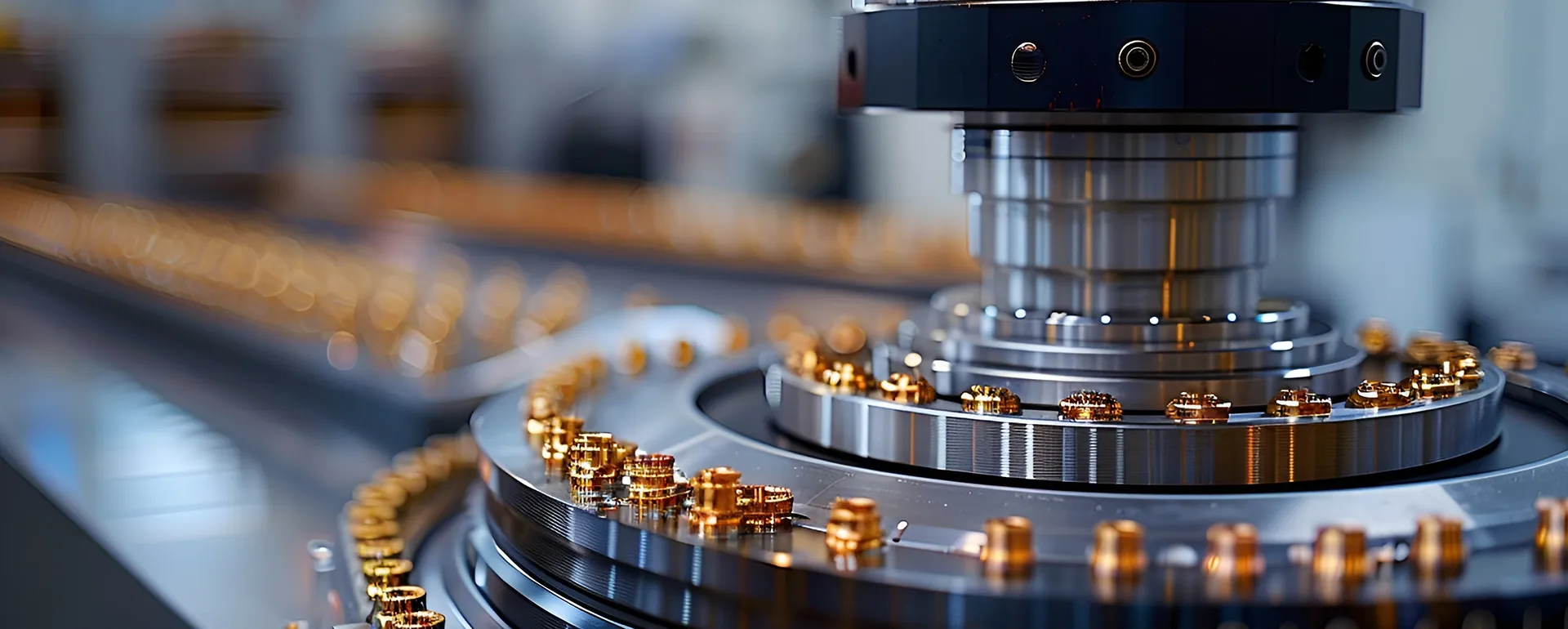

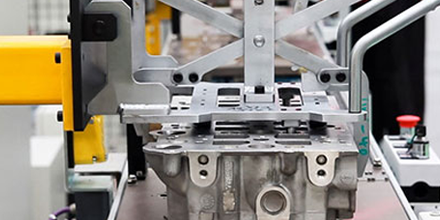

Zinc/Aluminum Alloy Die Casting

We strive for excellence in the manufacturing process of our products, introduce advanced mechanical equipment, and constantly seek innovation and improvement to enhance the quality and competitiveness of our products.

Plastic Injection Molding

Customization and production of various plastic products

- BLOG -

Latest Blog News